The Relationship Between Employee Health and Hygiene Violations and Foodborne Illness Complaints

Caitlin Ebner, RS

Environmental Health Specialist -

City of Minnetonka, MN

Abstract

This retrospective study identified employee health and hygiene violations from routine inspections at high-risk food service facilities in Minnetonka, Minnesota, compared to the frequency of customer complaints of foodborne illness reported to the Minnesota Department of Health. High-risk restaurant facilities in Minnetonka were evaluated based on specific violations observed during routine annual inspections in the years 2019-2022. Minnesota Food Code violations in four categories and 10 Conference for Food Protection (CFP) subsets were assessed: Supervision (CFP 1-2), Employee Health (CFP 3-5), Good Hygienic Practices (CFP 6-7), and Preventing Contamination by Hands (CFP 8-10). A total of 1,039 inspections from high-risk facilities in Minnetonka were analyzed. Results indicated that facilities without reported customer complaints of foodborne illness performed better than facilities with reported customer complaints of foodborne illness in all four violation categories. Analysis of the study revealed Supervision (CFP 1-2) and Preventing Contamination by Hands (CFP 8-10) violations were the most cited from the four categories for both facilities; with and without reported customer complaints of foodborne illness. As a result of this study, Minnetonka Environmental Health staff will continue to focus efforts on the importance of, and implementation of, self-inspection and active managerial control at high-risk facilities.

Keywords: Foodborne illness complaint, Self-inspection, Certified Food Protection Manager, Minnetonka

The Relationship Between Employee Health and Hygiene Violations and Foodborne Illness Complaints

Background

Minnetonka Public Health (MPH) is an environmental health agency that regulates food facilities in the city of Minnetonka, MN. Minnetonka environmental health specialists inspect approximately 235 high-risk food establishments in Minnetonka annually. This study focuses on facilities classified as high-risk, which engage in extensive to moderate food handling procedures. High-risk food facilities prepare ready-to-eat foods. Time/Temperature Control for Safety (TCS) foods are heated and cooled (temperatures pass through the danger zone two or more times), using Time as a Public Health Control (TPHC) in place of temperature control for safety, or a specialized process.

Employee health and hygiene violations investigated in this study were based on the Conference for Food Protection (CFP) marking system and standard throughout Minnesota (Conference for Food Protection, 2023). This study focused on the first ten CFPs listed on inspection reports, divided into four categories: Supervision CFP 1: Person In Charge present, demonstration of knowledge and performs duties; CFP 2: Certified Food Protection Manager, Employee Health; CFP 3: Management, food employee knowledge, responsibilities, and reporting; CFP 4: Proper use of restriction and exclusion and reporting; CFP 5: Clean-up of vomiting and diarrheal events, Good Hygienic Practices; CFP 6: Proper eating, tasting, drinking, or tobacco use; CFP 7: No discharge from eyes, nose, and mouth, Preventing Contamination by Hands; CFP 8: Hands clean and properly washed; CFP 9: No bare hand contact with ready-to-eat foods or written procedures are properly followed; CFP 10: Adequate handwashing sinks properly supplied and accessible.

High-risk facilities are required to employ a full-time Certified Food Protection Manager (CFPM) (Minnesota Food Code, 2019). Certified Food Protection Managers obtain credentialing through the Minnesota Department of Health after completing education through an ANSI-accredited training provider (Minnesota Food Code, 2019). CFPMs act as the person-in-charge of food safety for the licensed facility and ensure employee health and hygiene standards are followed. They oversee a robust list of duties, including self-inspection, reporting customer complaints of illness to the health authority, and maintaining an accurate employee illness log. CFPMs are responsible for completing self-inspections, pertinent to the daily operations of the facility, as required by the City of Minnetonka (815.025. Self-Inspection Program), and the Minnesota Food Code (MN Rules 4626.0033F). Required self-inspection components often include handwashing procedures, food temperature hot and cold holding, verification of foods received at the proper temperature, proper cooling of TCS foods, and verification of sanitizer concentration and high temperature in dishwashing machines. Due to continual staff turnover, licensed food facilities may lack a full-time Certified Food Protection Manager. When a licensed food facility is without a CFPM, there may be increased employee health violations, failure to report customer complaints of illness, and partial-to-incomplete facility self-inspection. The objective of this study was to determine if there was a relationship between employee health and hygiene violations observed during routine inspections, and customer complaints of foodborne illnesses at high-risk food service establishments.

Problem Statement

The relationship between employee health and hygiene violations and customer complaints of foodborne illness in Minnetonka is unknown.

Research Questions

What percentage of facilities with Supervision violations (CFP 1-2) have customer complaints of foodborne illness?

What percentage of facilities with Employee Health violations (CFP 3-5) have customer complaints of foodborne illness?

What percentage of facilities with Good Hygiene Practice violations (CFP 6-7) have customer complaints of foodborne illness?

What percentage of facilities with Preventing Contamination by Hands violations (CFP 8-10) have customer complaints of foodborne illness?

How many reports of foodborne illness were received in each year 2019-2022 in facilities with violations versus received by facilities with no violations?

Methodology

Employee health and hygiene violations investigated in this study were based on the Conference for Food Protection (CFP) marking system and standard throughout Minnesota (Conference for Food Protection, 2023). This study focused on the first ten CFPs standards listed on inspection reports, divided into four categories: Supervision CFP 1: Person In Charge present, demonstration of knowledge and performs duties; CFP 2: Certified Food Protection Manager, Employee Health; CFP 3: Management, food employee knowledge, responsibilities, and reporting; CFP 4: Proper use of restriction and exclusion and reporting; CFP 5: Clean-up of vomiting and diarrheal events, Good Hygienic Practices; CFP 6: Proper eating, tasting, drinking, or tobacco use; CFP 7: No discharge from eyes, nose, and mouth, Preventing Contamination by Hands; CFP 8: Hands clean and properly washed; CFP 9: No bare hand contact with ready-to-eat foods, or written procedures are properly followed; CFP 10: Adequate handwashing sinks properly supplied and accessible.

This study evaluated CFP standards 1-10 and their violation frequencies compared to reported customer complaints of employee illness at high-risk facilities in Minnetonka. Violations were collected using the City of Minnetonka Environmental Health Division’s health inspection report software, PIMS (Permit and Inspection Management System), a product of LOGIS (Local Government Information Systems). For this study, inspection report data from 2019 through 2022 was analyzed to determine: facility name, licensing type, and all violations and marked outcomes in CFP standards 1-10. Violations could be marked IN/OUT/NA/NO: in compliance, out of compliance, not applicable, or not observed.

Customer complaints of foodborne illnesses from the Minnesota Department of Health’s Foodborne Illness Reporting Center for Minnetonka were reviewed. Complaint data was gathered from the years 2019 through 2022. Complaint data was examined to generate a single list of all facilities with associated customer complaints of illness in the four-year time frame, regardless of frequency.

Results

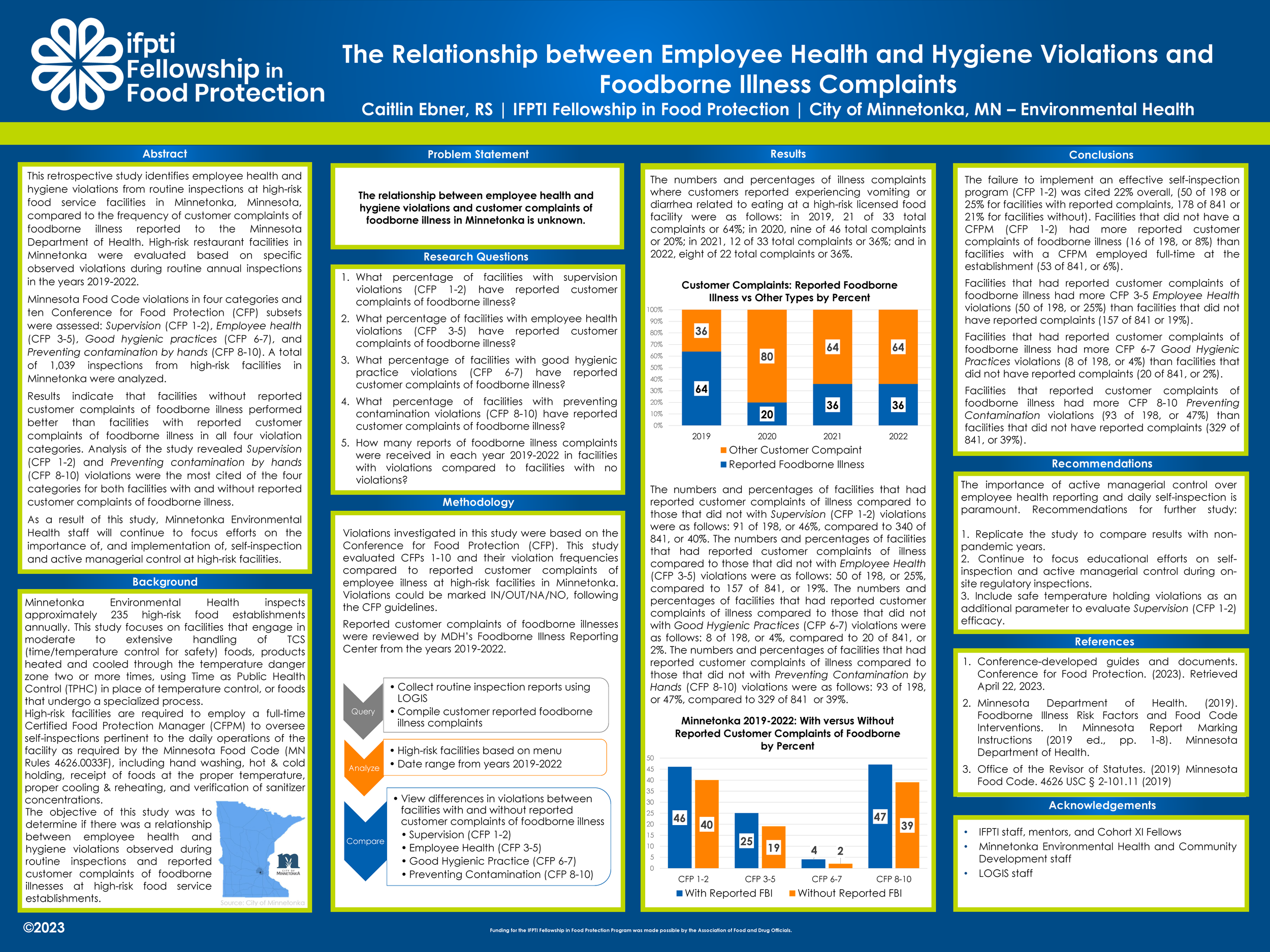

In Minnetonka, the percentages of total illness complaints where customers reported experiencing vomiting or diarrhea related to eating at a high-risk licensed food facility were as follows:

In 2019, 64% of customers reported experiencing vomiting or diarrhea related to eating at a high-risk licensed food facility. In 2020, 20% of customers reported experiencing vomiting or diarrhea related to eating at a high-risk licensed food facility. In 2021, 36% of customers reported experiencing vomiting or diarrhea related to eating at a high-risk licensed food facility. In 2022, 36% of customers reported experiencing vomiting or diarrhea related to eating at a high-risk licensed food facility.

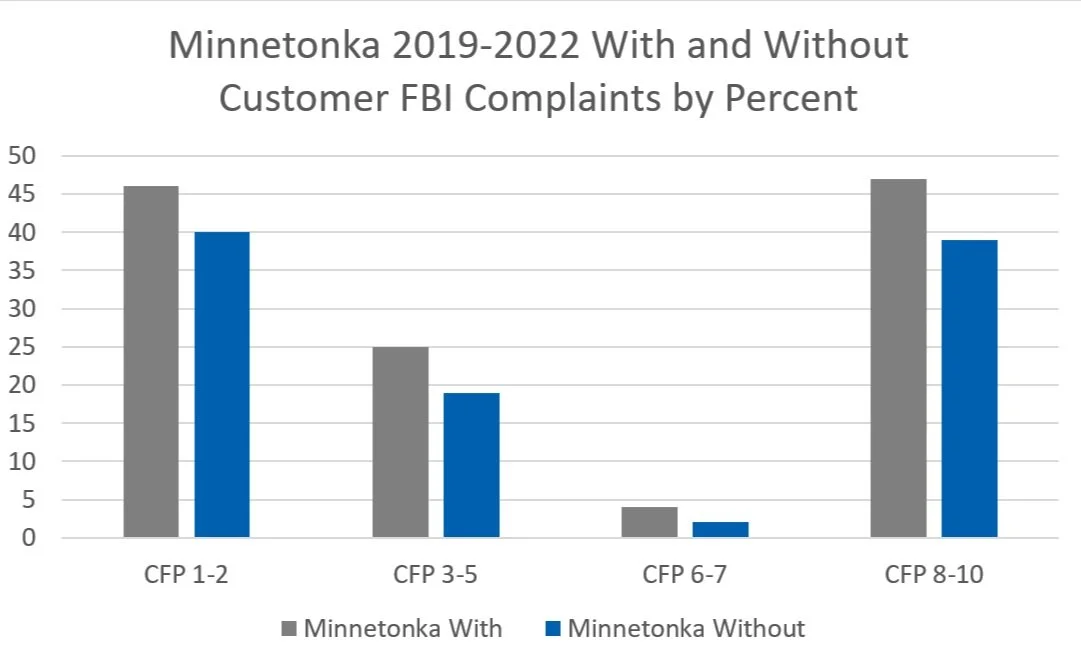

In Minnetonka, the percentage of facilities that reported having customer complaints of illness was 46%, compared to 40% who did not have Supervision (CFP 1-2) violations.

In Minnetonka, the percentages of facilities which had reported customer complaints of illness compared to those that did not with Employee Health (CFP 3-5) violations were as follows: Of 207 facilities, 25% reported customer complaints of illness, while 19% did not.

In Minnetonka, the percentages of facilities that had reported customer complaints of illness compared to those that did not with Good Hygienic Practices (CFP 6-7) showed that of 28 facilities, 4% had reported customer complaints of illness while 2% did not report customer complaints of illness.

The percentages of facilities that had reported customer complaints of illness compared to those that did not with Preventing Contamination by Hands (CFP 8-10) showed violations 47% received reports while 39% did not receiving reports of customer complaints of illness. Figure 1 below shows the comparison of the facilities with and without consumer complaints.

Figure 1

Minnetonka 2019-2022 With and Without Customer FBI Complaints by Percent

Conclusions

Analysis of the collected data led to the following conclusions:

The percentage of foodborne illness complaints compared to the total complaints received in 2019 was 64% for Minnetonka, higher than in 2020, 2021, and 2022 combined. The data suggests that the SARS-CoV-2 pandemic may have reduced the number of complaints received in Minnetonka during the pandemic.

In all four researched categories, Minnetonka high-risk facilities with reported customer complaints of foodborne illness had more violations than high-risk facilities that did not have reported customer complaints of foodborne illness.

The failure to implement an effective self-inspection program by facilities was cited in 22% of violations. Of the 1,039 facilities with reported FBI complaints, 25% had an effective self-inspection program, while 21% of facilities did not, based on overall inspection reports from 2019-2022. The self-inspection program is a component of Supervision (CFP 1-2).

Facilities that did not have a CFPM had more reported customer complaints of foodborne illness (8%) compared to facilities with a CFPM employed full-time at the establishment (6%). The requirement to employ a CFPM is a component of Supervision (CFP 1-2).

Facilities that reported customer complaints of foodborne illness had more CFP 3-5 Employee Health violations (25%) than facilities that did not have reported complaints (19%).

Facilities that reported customer complaints of foodborne illness had more CFP 6-7 Good Hygienic Practices violations (4%) than facilities that did not have reported complaints (2%).

Facilities that reported customer complaints of foodborne illness had more CFP 8-10 Preventing Contamination by Hands violations (47%) than facilities that did not have reported complaints (39%).

Recommendations

Based on the findings of this project, the importance of active managerial control over employee health reporting and daily self-inspection is paramount.

Recommendations for further study are as follows:

This study could be replicated to compare results with non-pandemic years.

Continue to focus educational efforts on self-inspection and active managerial control during on-site regulatory inspections.

The inclusion of safe temperature holding violations would give an additional parameter to evaluate Supervision (CFP 1-2) efficacy.

Acknowledgements

The author wishes to thank IFPTI for awarding the opportunity to focus on food safety research within Minnetonka. Gratitude is extended to IFPTI staff, mentors, and Cohort XI Fellows. In addition, the author acknowledges the Minnetonka Environmental Health staff.

References

Conference-developed guides and documents. Conference for Food Protection. (2023). http://www.foodprotect.org/guides-documents/

Minnesota Department of Health. (2019). Foodborne illness risk factors and food code interventions. In Minnesota Report Marking Instructions (2019 ed., pp. 1-8).

Minnesota Department of Health. Office of the Revisor of Statutes. (2019) Minnesota Food Code. 4626 USC § 2-101.11 (2019). https://www.revisor.mn.gov/rules/4626/U.S. Food & Drug Administration: Retail Food Risk Factor Study (2021). https://www.fda.gov/media/148247/download

Author Note

Caitlin Ebner, Environmental Health Specialist

City of Minnetonka, MN Environmental Health

This research was conducted as part of the International Food Protection Training Institute’s Fellowship in Food Protection, Cohort XI.

Correspondence concerning this article should be addressed to:

Caitlin Ebner, City of Minnetonka Environmental Health, 14600 Minnetonka Blvd. Minnetonka, MN 55345

Funding for the IFPTI Fellowship in Food Protection Program was made possible by the Association of Food and Drug Officials.