Risk Factor Assessment of Sushi Rice Operations: HACCP vs. TPHC

Mailee Moua

Environmentalist Senior -

Hennepin County Public Health

Abstract

The two most common methods of making sushi rice, while controlling foodborne illness risks in Hennepin County, Minnesota, are by following Time as Public Health Control (THPC) plans and Hazard Analysis Critical Control Point (HACCP) plans. Hennepin County has not investigated the risk factor violation occurrence rates in sushi rice operations prior to 2021. A mixed methodology approach using 2021 inspection data and surveys was used to assess food safety violation occurrence rates and the challenges and barriers in food safety for sushi chefs and establishments. TPHC establishments were reported as having the highest risk factor violation occurrence rate in Protection from Contamination (54%), Improper Holding of Temperatures and Time (31%), and Unsafe Sources (54%). HACCP establishments were observed to have the highest violation occurrence rates in improper temperatures (22%), unsafe sources (11%), and protection from contamination (6%). Priority intervention recommendations are to address cleaning and chemical sanitization in TPHC facilities, and to ensure that sushi operators using HACCP plans are following and understand their written HACCP plans.

Keywords: Sushi, acidification, HACCP, Time as Public Health Control, risk factors

Risk Factor Assessment of Sushi Rice Operations: HACCP vs. TPHC

Background

The number of sushi restaurants have steadily increased in Hennepin County. Sushi rice is a traditional Japanese dish that is cooked and mixed with vinegar to serve at room temperature with seafood. Many sushi operating establishments control microbial growth by adhering to food safety practices such as cold holding foods in refrigerators or holding foods at room temperature under a Time as a Public Health Control (TPHC) plan. A TPHC plan allows for ready-to-eat time/temperature controlled for safety (TCS) foods to be held at room temperature but then discarded after four hours to prevent microbial growth. Sushi operators following the TPHC process are not required to obtain a variance to operate outside of Minnesota (MN) Food Code 4626. However, these establishments are required to have a written TPHC plan and documentation onsite.

In contrast to TPHC, some establishments choose to acidify their sushi rice using vinegar, with validation that the rice is safe to be held at room temperature for an extended amount of time, outside of mechanical hot and cold holding. The acidification of sushi rice process differs from TPHC process and is considered a specialized process that operates outside of the Minnesota Food Code. Due to the increased potential health risks in specialized processes, acidification of sushi rice requires prior variance approval and the submittal of a Hazard Analysis Critical Control Point (HACCP) plan to the Health Department that address and controls for hazards in this specialized process. MN Food Code 4626.0395 states that TCS foods are to have internal temperatures of less than 41°F for cold holding or greater than 135°F for hot holding to prevent microorganism growth. The acidification of sushi rice with vinegar renders rice to have a pH concentration that would make it no longer a TCS food. Studies conducted on the efficacy of sushi rice acidification have shown that rice may be held for up to 24 hours and acidification will inhibit the growth of C. perfringens and B. cereus if pH concentrations of vinegar are lower than 4.2 (Mohammad, 2020).

Part of a study conducted by the Minnesota Department of Health in 2016 (Hedeen, 2016) observed that sushi operations using TPHC were not complying with the Minnesota 4626 Food Code requirements. The study found that, of the 40 restaurants surveyed, 85% of restaurants were preparing sushi rice under a TPHC plan, and 26% of those restaurants had a written TPHC plan onsite. Of the restaurants that were using TPHC, 53% were keeping track of time. With 85% of sushi establishments preparing rice under the TPHC plan, the concern for Hennepin County is that rice served under TPHC plans may require more food safety interventions and oversight.

In 2021, 36 establishments in Hennepin County were preparing sushi rice under a TPHC plan, and 21 establishments were preparing sushi rice under an approved acidification variance and HACCP plan. A general risk factor study was conducted in Hennepin County in 2021, and an inspection reporting tool was created to extract risk factor and violation data for The Centers for Disease Control’s (CDC) top five foodborne illness risk factors: Protection from Contamination, Personal Hygiene, Approved Source, Holding for Temperature and Time, and Adequate Cooking Temperatures. An assessment of risk factor violations in sushi operating establishments in Hennepin County has not been conducted. In addition to exploring inspection data for food safety violations, reviewing sushi chef surveys may reveal operation concerns and barriers related to food safety in Hennepin County jurisdiction. A risk assessment may help provide food safety interventions to reduce foodborne illnesses and violations in Hennepin County sushi establishments.

Problem Statement

Hennepin County Environmental Health (HCEH) has not assessed the CDC’s top five foodborne illness risk factor violations in sushi rice operations that use the HACCP plan versus the TPHC plan.

Research Questions

What is the occurrence rate for food safety violations in Hennepin County sushi establishments?

What, if any, are the differences in risk factor violations between TPHC and HACCP sushi operations?

What are the food safety challenges faced by sushi operating establishments?

Methodology

This research followed a mixed methodology study design and incorporated quantitative and qualitative data. Data gathering occurred in multiple phases.

Phase 1: Risk Factor Violation Review. HCEH uses digital inspection software, Digital Health Department (DHD), and licensed each sushi establishment as either operating with a HACCP plan and a variance, or as a general establishment with no HACCP plan. Risk factor violations for all the identified sushi rice operating establishments were pulled using the Risk Factor Study (RFS) tool in the DHD software. Establishments that were not inspected in 2021 were removed from data analysis. The RFS tool identified violations of the CDC top five foodborne illness risk factors; the DHD associated data items; and the MN Food Code reference which were reported as out of compliance in 2021 routine inspection reports. Data items and Food Code reference follows what was noted in US FDA’s RFS Protocol for Data Collection (2015) and Minnesota Food Code MN4626. Violations were sorted by operations and analyzed with the support of the Public Health Data and Assessment team.

Phase 2: Sushi Operations Survey. Qualitative data was obtained through email and in-person surveys. All sushi operating establishments in Hennepin County were contacted via the inspection record’s listed email for persons in charge of sushi operations. Establishments were sent an email introducing the voluntary survey for sushi rice operations and an attached Microsoft Forms survey link. There were 22 questions on the survey that was written in plain English language for all levels of reading, including those who are limited English speakers. Due to a lack of e-mail response from sushi chefs, licensed establishments were selected through a random list generator tool using the online platform tool, www.random.org to generate a random selection of sushi operation for in-person sushi chef interviews. In order to account for uniformity in data collection, a script with possible answer choices was created to help guide the sushi chefs during the survey, along with one question for an open-ended response for additional food safety concerns. Survey questions focused on sushi chef training, knowledge and rating of operations, concerns about food safety, challenges in cleaning of kitchens, and familiarity of Fish Letter of Guarantee.

Phase 3: Public Health Intervention and Good Retail Practice Violation Review. Violations observed during routine inspections, HACCP audits, and HACCP variances were reviewed for all sushi kitchens and bars.

Public health intervention and good retail practice violations were pulled from DHD database and were compared with risk factor violations to observe any additional trends.

Results

Of the 57 licensed sushi operating facilities in Hennepin County in 2021, 31 establishments’ routine inspection reports were reviewed for violations. Licensed HACCP establishments were corporately owned or franchised, and the TPHC establishments were individually and locally owned businesses.

There were 13 establishments with TPHC plans and 18 establishments with HACCP plans. Figure 1 is a visual of the CDC’s Top Five Risk Factor violations between THPC and HACCP establishments. TPHC establishment data showed that the top three risk factor violations were Protection from Contamination (54%), Improper Holding of Temperatures and Time (31%), and Unsafe Sources (54%). The top three risk factor violations for HACCP establishment were Improper Temperatures (22%), Unsafe Sources (11%), and Protection from Contamination (6%). Neither TPHC nor HACCP establishments had any noted violations for Poor Personal Hygiene or Inadequate Cooking Risk Factors.

Figure 1

Risk factor violation rates for sushi rice operating establishments HACCP and TPHC

In TPHC establishments, the top risk factor violation was in Protection from Contamination, observed in inspection data item 16 from inspection reports citing improper chlorine concentration levels required for sanitizing food contact surfaces. A top violation for TPHC establishments was Missing or Inadequate Fish Letters of Guarantee, also known as parasite destruction letters, which provide documentation of proper freezing or feeding methods of fish to prevent parasite growth after raw fish consumption. The top public health violation was in Preventing Contamination by Hands as noted in inspection data items 8,9, and 10, and Utensils, Equipment, and Vending. The top violation of Good Retail Practice for TPHC establishments was in Utensils, Equipment, and Vending, as noted in inspection data items 47, 48, and 49. In HACCP establishments, the top risk factor violation was in Improper Holding of Time/Temperatures, observed in inspection data item 22. The top public health intervention violation was in Conformance with Approved Procedures in HACCP plans in data item 29. The top Good Retail Practice violation for HACCP establishments was in Food Temperature Control as noted in inspection data items 33, 34, 35, and 36. Completed survey results (n=7) were received from four HACCP chefs and three TPHC chefs. Operators all reported they had attended a food safety course and 71% were Certified Food Protection Managers (CFPM) in Minnesota. All operators noted that they were trained in food safety in English (100%) and their primary languages were Burmese (57%), Spanish (29%), and Mandarin (14%).

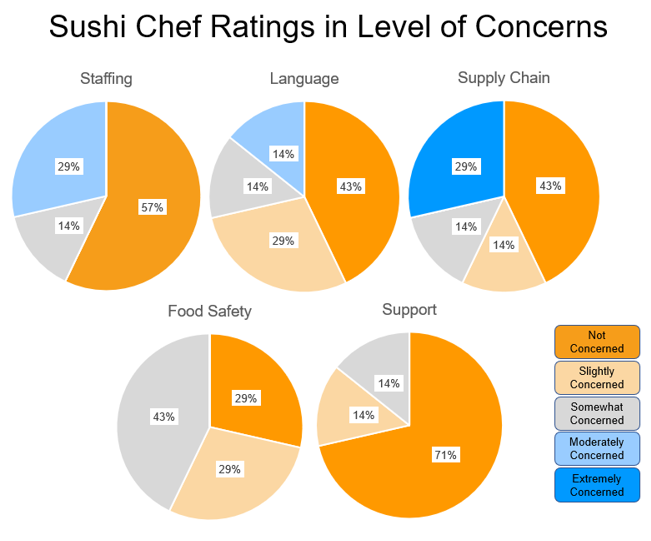

Most sushi chefs (n=6) had six or more years handling sushi rice and one chef had five years of sushi rice experience. Sushi chefs rated their level of concern regarding staffing, language, supply chain, food safety, and resources as illustrated in Figure 2. Supply chain concern was noted to have 29% who expressed extreme concerns and 28% of chefs expressed moderate concerns regarding staffing. The least amount of concern for chefs was in resource support. Chefs rated the highest barrier to cleaning was due to staffing (29%) and that time was the least barrier to cleaning (86%).

Figure 2

Levels of concerns in staffing, language, supply chain, food safety, and support as reported by Sushi chefs

Chefs who were under TPHC plans (n=3) had a self-reported average of 4.67 rating, from a scale of 1 (low) to 5 (high), for their confidence in understanding their written plans. However, 67% of establishments did not have their written TPHC plans onsite. Chefs under HACCP plans (n=4) had a self-reported average of 3.5 rating, on a scale of 1 (low) to 5 (high), for their confidence in understanding their written plans, and all noted that they had their plans onsite. All HACCP chefs noted that their written plans require a pH of 4.1 or less for sushi rice and that they stored their rice at room temperature for no more than 24 hours. All facilities served raw fish in their establishment, with 86% of chefs being familiar with their fish letters of guarantee. Surveyed establishments did not use chlorine as their sanitizer chemical of choice (n=7).

Conclusions

Surveys indicated that chefs rated no cleaning barriers in their kitchens, however, inspection data indicated that cleaning should be a food safety priority, particularly in the TPHC establishments due to the prevalence of inspection violations noted in cleaning, and improper chlorine concentration levels. In addition to the high violation occurrence rate for Protection from Contamination, violation data for Good Retail Practices indicated that there is a high count of violations in utensil, equipment, and facility cleaning and storage.

Overall, the top HACCP violation noted in inspection reports was a lack of complying with their HACCP plan, as noted as data item 29R. The self-reported average rating for how well chefs understood their HACCP written plans was noted at an average of 3.5, from a scale of 1 to 5. Inspector notes indicated non-compliance with HACCP plans due to incomplete or missing HACCP logs and lack of verifications on logs.

Lack of chef confidence in understanding written HACCP plans may contribute to non-compliance through lack of verification and storage of HACCP logs. Chefs indicated that English was their second language which may be another contributing factor as to why HACCP chefs lacked confidence in following their written plans. One operator stated, “My friends help translate [inspection reports]. Would be helpful to have Burmese inspectors.” Another chef stated, "I have been making sushi for 10 years, so I know about fish and food safety well. I can speak English better than reading. HACCP plan is not easy to read for me."

A limitation of this study was that not all licensed sushi facilities in Hennepin County were inspected in 2021 due to COVID-19 routine inspection restrictions.

Recommendations

Direct educational and outreach interventions to sushi operators is recommended, in multiple languages and platforms, including food safety fact sheets, social media, and in-person or virtual training courses.

Outreach materials in multiple languages should be provided to all sushi establishments with a focus on approved sources, improper holding temperatures/times, and protection from contamination risk factors. Multi-lingual staff would be beneficial to the health department.

Foodborne illness interventions should be focused in TPHC operations as they had higher rates of violations compared to establishments that followed HACCP plans.

Hennepin County foodborne illness interventions should include training in proper cooling and cold holding methods for sushi and sushi rice, what chlorine concentrations are effective for cleaning, and general cleaning guidelines for TPHC establishments.

Outreach efforts to HACCP establishments should focus on how to cool from ambient, and how to properly cold hold finished sushi products before placing in customer cold hold units.

Future studies should investigate corporate ownership versus individual ownership of sushi operations.

Acknowledgements

Acknowledgements to IFPTI and support staff for their support and funding, Kathy Fedder as my research mentor, Cohort XI for their support and camaraderie, Nicole Hedeen from Minnesota Department of Health Environmental Health Epidemiology, and Hennepin County Environmental Health team and the Public Health Data and Analytics team for providing support and data to this research.

References

Hedeen, N. (October 01, 2016). Restaurant policies and practices for serving raw fish in Minnesota. Journal of Food Protection (2016) 79 (10): 1813–1819. https://meridian.allenpress.com/jfp/article/79/10/1813/174555/Restaurant-Policies-and-Practices-for-Serving-Raw

Mohammad, Z. Payton, L., & Sirsat, S. (September 2020). Efficacy of sushi rice acidification: Quantification of Bacillus cereus and Clostridium perfringens during simulation of retail practices. Science Direct volume 131. https://doi.org/10.1016/j.lwt.2020.109884

Author Note

Mailee Moua, Environmentalist Senior

Hennepin County Public Health, MN

This research was conducted as part of the International Food Protection Training Institute’s Fellowship in Food Protection, Cohort XI.

Correspondence concerning this article should be addressed to:

Mailee Moua, Hennepin County Public Health at m.moua@hennepin.us

Funding for the IFPTI Fellowship in Food Protection Program was made possible by the Association of Food and Drug Officials.