The Food Safety Modernization Act: What Do Processors Know About the Hazard Analysis and Food Safety Plan Requirements, and Where Do They Anticipate Finding Assistance?

Karla Ann Horne

Food Safety Scientist

Michigan Department of Agriculture and Rural Development

International Food Protection Training Institute (IFPTI)

2011 Fellow in Applied Science, Law, and Policy: Fellowship in Food Protection

Abstract

The 2011 Food Safety Modernization Act (FSMA), Section 103, requires food processors to develop a hazard analysis and preventive controls plan for all of their processes. The U.S. Food and Drug Administration (FDA) plans to publish rules implementing these FSMA requirements in 2012. An electronic survey was sent to food processors in Michigan to determine a baseline knowledge regarding these new requirements. The survey also asked where the processors would seek assistance, if needed, in complying with the upcoming requirements. The results of this survey indicate a significant disparity in the knowledge base between processors grossing greater than $10 million a year and processors grossing less than $499,999 a year. The results also show that firms expect the primary source of assistance in complying with the FSMA requirements to be the Michigan Department of Agriculture and Rural Development (MDARD).

Background

In March 2009, President Obama established a working group to focus on food safety in the United States. This working group included representatives from the U.S. Food and Drug Administration (FDA), the Food Safety and Inspection Service (FSIS), the Centers for Disease Control and Prevention (CDC), the Department of Homeland Security (DHS), the Department of Commerce, the Department of State, the U.S. Environmental Protection Agency (EPA), and several other agencies. In July 2009, the Food Safety Working Group recommended three core food safety principles to guide a more focused public health-based approach to developing a food safety system (Food Safety Working Group, 2009): (1) Preventing harm to consumers, (2) Improving the effectiveness of inspections, enforcement, and data analysis, and (3) Improving response and recovery to foodborne illness outbreaks. Many of this working group’s recommendations are included in the Food Safety Modernization Act (FSMA), which was signed into law in January 2011. Among the many provisions, this law requires food businesses that hold, package, process, or manufacture foods to develop a food hazard analysis and preventive controls plan. A hazard analysis requires firms to identify and evaluate hazards associated with food facilities, food processing or handling practices, and the foods or food products. This analysis must consider biological, chemical, physical, radiological, and other hazards. Once the hazards have been identified and documented, the firm must develop and implement a plan to control for, or significantly minimize, these hazards within the facility at each point where these potential food safety risks may occur (Food Safety Modernization Act of 2011). Functionally, the FSMA-required food safety plan is similar to a Hazard Analysis Critical Control Point (HACCP) Plan. However, at this time, only firms that process juice, seafood, or low-acid canned foods are formally required to develop and operate using a HACCP plan. In May 2011, the FDA issued a Notice of Request for Comments for “Preventive Controls for Registered Human Food and Animal Food/Feed Facilities” to gather information from interested parties and stakeholders regarding the development of the forthcoming regulations and guidance on hazard analysis and preventive control plans for human food and animal feed facilities (Preventive Controls for Registered Human Food and Animal Food/Feed Facilities, 2011).

As the federal government moves forward in addressing the need for food safety plans to help ensure a safer food supply, there may be a substantial impact on businesses that historically have not been required to have these plans. Each plan will be unique, and tailored to each firm’s specific food safety needs and risks. Regulators are currently unclear how informed processors are regarding the requirements of FSMA and where processors anticipate finding assistance in developing their hazard analysis and food safety plans.

If firms are ignorant of the food safety rules, regulations, and legislative requirements that govern their business or they do not see the value in the regulations, the firms will not be motivated to comply (Yap and Fairman, 2006). For example, a study conducted in 2004 in the United Kingdom found that food establishment operators believe that the enforcing officer (i.e., regulatory staff), rather than the firm, is responsible for the analysis of the firm’s potential food safety hazards. This study also determined that small and medium-sized food businesses had significant barriers to compliance with regulations. The primary reasons noted in the study were lack of knowledge, lack of awareness, lack of motivation, and lack of a management system. Additionally, the general level of knowledge about hazard analysis was poor, with about 25% of the firms surveyed having no knowledge. The authors of the study concluded that firms that are well-informed and invested in their planning and process controls will more likely comply with regulations (Yap and Fairman, 2006).

Problem Statement

The general knowledge level of food processors in Michigan regarding the FSMA requirements for food manufacturers to perform a hazard analysis and develop a preventive control food safety plan is unknown. If processors lack the foundational knowledge to develop and implement a hazard analysis and food safety plan, regulators are unclear where Michigan processors intend to secure assistance and resource information. Regulators assume, but do not know, if there are differences in knowledge levels based upon a processor’s size.

Research Questions

1. Is there a lack of knowledge among Michigan food processors about FSMA requirements concerning food safety hazard analysis?

2. Is there a lack of knowledge among Michigan food processors about FSMA requirements concerning preventive controls (food safety plans)?

3. Where will businesses in need seek assistance in understanding and complying with FSMA requirements?

Methodology

An electronic survey was administered to a representative sample of Michigan food processors using a Web-based survey program. The 10-question survey was designed to determine respondents’ baseline awareness of the FSMA hazard analysis and food safety plan requirements. The survey also requested information about where respondents planned to secure assistance, if needed, to comply with the FSMA. Additionally, the survey collected basic information about the firms’ size, geographic location, and general processing type.

The survey was sent to 401 licensed processors in the state of Michigan who have provided e-mail addresses to the Michigan Department of Agriculture and Rural Development as part of the licensure process. Survey recipients had approximately three weeks to complete and return the survey. Forty-nine percent of these processors (198) responded to the survey. Responses to the survey were blind, so that no individual processor could be identified. Responses were analyzed to determine if Michigan food processors are knowledgeable of the FSMA requirements to develop a hazard analysis and a food safety plan, and where processors plan to acquire assistance, if necessary, in meeting the requirements. The responses were also studied to discover whether differences in knowledge exist across general industry types and industry sizes. Of the 198 respondents, 23% (46), were excluded from this analysis because their production is already regulated under existing HACCP regulations for juice or seafood or they did not properly complete the survey. All data analysis was based on the responses provided by the remaining 152 respondents who properly completed the survey and are not currently regulated under an existing HACCP regulation.

Results

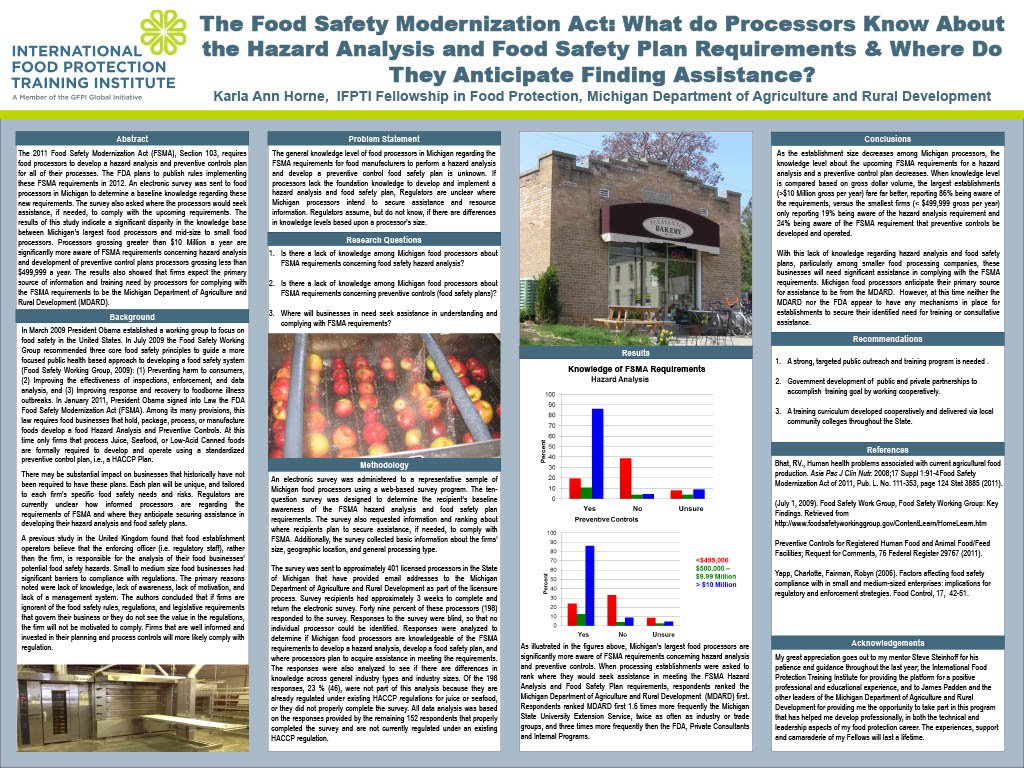

Approximately 42% of processors were aware of the FSMA requirement to perform a written hazard analysis, and 50% of processors were aware of the FSMA requirement to develop and implement a preventive control plan (food safety plan). When the data were analyzed to compare processor knowledge based on processor size, a disparity in knowledge was revealed. Eighty-six percent of firms grossing greater than $10 million a year are aware of the FSMA requirements for written hazard analysis and food safety plans (see Figure 1).

Nineteen percent of establishments grossing less than $499,999 a year reported having knowledge of the hazard analysis requirement, and only 24% of those establishments reported having an understanding of the food safety plan requirements (see Figure 2). A significant majority of respondents, 79%, are processors of non-potentially hazardous foods (such as baked goods, jams/jellies, coffee roasters, etc.); therefore a statistical comparison of knowledge between types of processors was not feasible.

When processing establishments were asked to rank where they would seek assistance in meeting the FSMA Hazard Analysis and Food Safety Plan requirements, respondents ranked the Michigan Department of Agriculture and Rural Development (MDARD) first. Respondents ranked MDARD first 1.6 times more frequently than the Michigan State University Extension Service, twice as often as industry or trade groups, and three times more frequently than the FDA, private consultants, or internal programs.

Conclusions

When the data are aggregated and analyzed for the Michigan food processing industry as a whole, the results indicate that the food processing industry is relatively aware of the new hazard analysis and food safety plan requirements set forth in the FSMA. However, when the data are segmented and analyzed based on predefined categories for establishment size, a different picture emerges. As the establishment size decreases, the knowledge level about the upcoming FSMA requirements for a hazard analysis and a preventive control plan decreases. When knowledge level is compared based on gross dollar volume, the largest establishments (>$10 million gross per year) fare far better, with 86% report being aware of the requirements. Only 19% of the smallest firms (<$499,999 gross per year) reports being aware of the hazard analysis requirement, and 24% reports being aware of the FSMA requirement that preventive controls be developed and implemented.

With the lack of knowledge regarding hazard analysis and food safety plans, particularly among smaller food processing companies, these businesses will need significant assistance in complying with the FSMA requirements. Michigan food processors anticipate their primary source for assistance to be the MDARD. However, at this time neither, the MDARD nor the FDA appears to have any mechanisms in place for establishments to secure their identified need for training or consultative assistance.

Recommendations

As discussed previously, establishments that are knowledgeable about regulations governing their business and invested in the development of this new hazard analysis and food safety plan will be more likely to be successful in complying with food safety regulations (Yapp and Fairman, 2006). A strong, targeted public outreach and training program is needed. The MDARD lacks the resources and personnel to perform this type of outreach. Likewise, as a result of budget cuts and loss of extension grants, Michigan’s land grant universities are unable to meet all of the industries’ needs for high-value, low-cost training.

Although neither MDARD nor the land grant universities can provide this critical training alone, perhaps MDARD can develop other public and private partnerships that can accomplish this training goal by working cooperatively. A training curriculum could be developed cooperatively and delivered at local community colleges throughout the state. Community colleges are already offering a large variety of technical courses targeted at continuing education and training. Community college staff members are skilled educators. Community colleges are conveniently located throughout the state and could provide the training in a cost-effective manner once a curriculum was developed (Marguerite Cotto, Vice President of Life Long Learning, Northwest Michigan College, personal communication, December 20, 2011). Strategically located and knowledgeable MDARD Food Division staff could supplement and enhance training by serving as subject matter experts.

Acknowledgements

My great appreciation goes out to my mentor, Steve Steinhoff, for his patience and guidance throughout the last year; to the International Food Protection Training Institute for providing the platform for a positive professional and educational experience; and to James Padden and the other leaders of the MDARD for providing me the opportunity to take part in this program, which has helped me develop professionally, in both the technical and leadership aspects of my food protection career. The experiences, support, and camaraderie of my Fellows will last a lifetime.

Corresponding Author

Karla Ann Horne, Michigan Department of Agriculture and Rural Development

Email: hornek@michigan.gov

References

Food Safety Modernization Act of 2011, Pub. L. No. 111-353,124 Stat. 3885 (2011).

Food Safety Working Group. (July 1, 2009). Food Safety Working Group: Key Findings. Retrieved from http://www.foodsafetyworkinggroup.gov/ContentLearn/HomeLearn.htm

Preventive Controls for Registered Human Food and Animal Food/Feed Facilities; Request for Comments, 76 Federal Register 29767 (2011).

Yapp, C. and Fairman, R. (2006). Factors affecting food safety compliance within in small and medium-sized enterprises: Implications for regulatory and enforcement strategies. Food Control, 17, 42-51.